If you are involved in woodworking designs, then you should be well aware of the amount of effort it takes to produce the desired results. If you want to put in less effort to get a quality product, then a smart wood CNC router kit is essential.

If you are thinking about buying a wood engraving machine but don’t know how to pick one, you can always come to TechPro and our team of professionals will provide you with a solution. You just need to tell us your needs and budget, and leave the rest to us.

In order to help you better understand and select the right automatic woodworking CNC machine, we have crafted the following guide, these instructions, guidelines will come in handy in your next choice.

What Is A CNC Wood Router?

CNC Wood Router is a CNC-controlled automated machine designed to perform precise 2D, 2.5D and 3D cutting, milling, engraving, drilling and slotting on a variety of woodworking projects. Projects that can be processed include wood crafts, sign making, cabinet making, door making, gift making, modeling, decorating, closet making and other furniture making.

A typical CNC wood router consists of several key components: bed frame, spindle, vacuum or T-slot table, controller, operating system, software, gantry, drives, motors, vacuum pumps, guides, pinion gears, rack and pinion, ballscrews, collets, limit switches, power supply, and other parts and accessories.

How Does A Wood CNC Router Machine Work?

CNC woodworking machines are operated by a computerized control system that precisely manipulates tools to perform complex cutting or engraving tasks. The machine’s workflow is as follows: the technician first uses CAD/CAM software to create a basic runtime program, which is then converted into a machine-readable sequence of instructions (G-code). The machine then reads the G-code and begins to perform the task.

The machine consists of several key components, including a sturdy bed frame, a spindle and a table (vacuum or T-slot) that holds the workpiece. The controller and operating system interpret the digital instructions and direct the motors and drives to move the gantry and spindle along a specified path. These movements are guided by precision components such as rails, ballscrews and rack and pinion to ensure precise positioning.

As the spindle rotates at high speed, it uses a variety of router bits to cut, carve, or engrave material according to a programmed tool path. An automatic tool changer switches between different cutter heads as needed for various operations, allowing for seamless switching between cutting, drilling and milling tasks.

Capable of executing complex designs with high precision and repeatability, woodworking CNC machines are an essential tool for modern woodworking, and their use increases both productivity and creativity.

Types Of Wood CNC Machines

There are several types of woodworking CNC machines, each suited to specific woodworking tasks and applications:

- 3-Axis Wood CNC Routers: For general cutting, carving and engraving tasks, it is the most common CNC wood engraving machine.

- 4-Axis Wood CNC Routers: Rotate the workpiece for more complex shapes and undercuts.

- 5-Axis Wood CNC Routers: They are capable of accurately creating complex and delicate designs, such as producing customized and intricate furniture, producing fine components such as molds and trims, and making precision parts.

- Rotary Wood CNC Router: This machine is mainly used for cylindrical objects and allows for detailed 3D engraving.

- ATC (Automatic Tool Changer) Wood CNC Engraving Machine: This type of machine has an automatic tool changer, which improves machining efficiency and produces more complex workpieces.

- Multihead CNC Woodworking Engraving Machines: Equipped with multiple spindles for simultaneous machining of multiple parts.

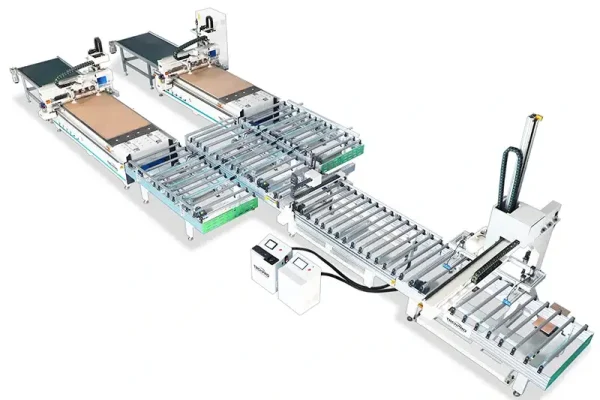

- Panel Furniture Production Line CNC Skeleton Milling Machine: Specialized for large-scale panel furniture production.

- Cabinet and door CNC milling machines: designed for cabinet and door manufacturing.

- Foam CNC Cutting and Milling Machines: Versatile machines that can handle both wood and foam materials.

Each type offers different machining capabilities to suit different woodworking projects, from simple to highly complex designs.

Applications

The CNC Wood Router is a versatile automated machine that can be used in a variety of industries to accomplish precise and efficient woodworking tasks. Primarily used for making furniture (including home furniture, office furniture, and custom cabinetry), the machine can be used in both industrial manufacturing and smaller operations such as small businesses, home stores, and educational institutions. The following is a breakdown of applications for woodworking engraving machines made by industry:

- Furniture Manufacturing: CNC woodworking engraving machines are valuable in making a wide variety of furniture, including home and office furniture, art and antiques, cabinets, doors, table and sofa legs, wood spindles, screens, headboards and MDF projects. They can also be used to make intricate wooden arts and crafts.

- Advertising: These machines are used to make fine signage and promotional materials.

- Mold Making: CNC routers can be used to precision make molds for a variety of applications.

- Skeletonizing and Embossing: Ideal for creating depth and dimension in woodwork through skeletonizing and embossing techniques.

- Wooden Cylinders and 3D Woodworking Projects: CNC routers help create cylindrical wood pieces and intricate three-dimensional designs.

- Sign Making and Custom Woodworking Plans: CNC routers are great for creating custom signs and executing detailed woodworking plans for specific needs.

With high precision, efficiency and versatility, CNC woodworking routers are an important tool for modern woodworking.

Technical Parameters

Brand | TechPro |

Models | 6060, 6090, 6012, 9015, 1212, 1325, 1530, 2030 |

Table Sizes | 2′ x 3′, 2′ x 4′, 4′ x 4′, 4′ x 6′, 4′ x 8′, 5′ x 10′, 6′ x 12′ |

Materials | Hardwood (Solid Wood), MDF (Medium-Density Fiberboard), Plywood, Particleboard, Wood Veneer |

Axis | 3 Axis, 4th Axis, 4 Axis, 5 Axis |

Capability | 2D Machining, 2.5D Machining, 3D Machining |

Control Software | Type3, Ucancam, Alphacam, Artcam, Cabinet Vision |

Price Range | $2,360 – $38,000 |

Price of CNC Wood Router

The cost of a CNC wood engraving machine is determined by factors such as table size, machine features, durability, power, quality, accuracy, speed, and brand. The exact price is determined by the machine components and individual needs, and usually ranges between $2,360 and $36,000.

In 2024, the average cost of owning a CNC Wood Router will be about $3,600 (from affordable home models to high-end commercial models).

Professional woodworking CNC routers range in price from $3,680 to $16,000 for hobbyists, depending on the machine’s capabilities and features. These machines offer advanced capabilities for individuals with experience in the woodworking industry. Commercial and industrial CNC machines are designed for heavy-duty applications and range in price from $18,000 to $120,000. These high-end machines are often equipped with a variety of integrated packages such as laminators, sanders, slotters, drills, mills and cutters. As a result, they are in high demand for the production of custom furniture, including personalized cabinets and doors.

It is important to consider the additional costs of duties, taxes and shipping when purchasing a CNC woodworking machine from overseas.

The most important factor is to determine if the machine is right for your specific woodworking needs, whether you are a small business owner or an industrial manufacturer.

Machine Price List

Types | Average Price | Minimum Price | Maximum Price |

Entry Level | $2,780 | $2,360 | $3,600 |

Hobby | $3,800 | $2,580 | $5,200 |

Professional | $7,980 | $5,680 | $12,800 |

Commercial | $22,000 | $12,000 | $80,000 |

Industrial | $28,000 | $18,000 | $100,000 |

Enterprise | $36,000 | $20,000 | $120,000 |

The price of a used CNC wood router is about 30% off this price.

How To Choose The Best CNC Wood Router For Woodworking?

In order to make your woodworking projects precise, efficient and creative, choosing the right CNC wood engraving machine is crucial. Understanding the key features and specifications of the many options available will help you make an informed choice. Now we’ll help you choose the CNC wood engraving machine that best meets your needs.

- Determine Project Requirements: Before delving into the technical specifications of the machine, assess the scope and scale of your project. Will you be working primarily on large-scale furniture or small handcrafted items? Different projects require routers with different capabilities; for example, a complex design may require a five-axis router, while simple tasks can be accomplished with a three-axis router.

- Consider the Size of the CNC Router and Table Kit: Both should be the same size as the material you intend to use. Table kit sizes typically range from 2′ x 3′ to 6′ x 12′. Make sure the milling machine can easily handle the largest workpieces.

- Evaluate Axis Capabilities: 4- and 5-axis routers can do more complex designs and undercuts, while 3-axis routers are suitable for most routine tasks. When choosing an axis configuration, consider the complexity of the design.

- Check Spindle and Motor Specifications: The power and speed of the spindle motor is critical when cutting different materials. Hardwoods and other dense materials require stronger spindles. Also check for features such as automatic tool changers, which allow for smooth transitions between different cutting tasks, thus increasing efficiency.

- Evaluate the Control System: The control system is the brain of the CNC milling machine and determines its accuracy and ease of use. Options include:

- Computer Controls: Provide an easy-to-use interface with high program compatibility, allowing for error correction and real-time previews.

- While they are space-saving and ideal for setups without a dedicated computer, joystick DSP controllers may not have preview capabilities.

- Integrated Controllers: For high-end applications, these controllers offer a wealth of interfaces and built-in controls, but can be more expensive and complex.

- Choosing the Right Router Bit: The best cutting and finishing results depend on the router bit you use. Consider the different types of bits:

- Flat-bottomed Bits are great for roughing and contouring.

- Spherical Bits are good for carving curved surfaces.

- To make a V-groove, use a V-groove bit.

- Tapered Heads: For 3D engraving and fine machining.

- Material Compatibility: Ensure that your CNC mill can machine the materials you will be working with, such as veneer, plywood, MDF or hardwood. Different tools can work with different materials, and choosing the right router head and spindle power will improve the performance of your machine.

- Budget Considerations: CNC Wood Router models range from entry-level to high-end models, and prices vary accordingly, so choose the right machine for your budget.

If you don’t know how to choose the right CNC wood router for you, please contact our sales team directly. Whether you want to buy a new CNC wood router or a used CNC wood router, just let us know your needs and budget, and we will provide you with the best solution in the shortest possible time.

Purchasing Process

We will recommend the most suitable stone CNC engraving machine for your specific requirements. Our team will assess your needs and develop the best solution for you.

After understanding your requirements, we will provide you with a detailed quote for the stone CNC milling machine. This will include the most suitable specifications, high quality accessories and a competitive price.

To avoid misunderstandings, both parties will thoroughly review and go over every detail, including technical parameters, specifications and commercial terms before moving forward.

We will send you a Proforma Invoice (PI) and sign the contract with you after you are satisfied with every detail.

We will start manufacturing your stone CNC milling machine as soon as we receive your signed sales contract and deposit. We will provide you with the latest production information at every stage.

The whole production process will be subject to regular inspection and strict quality control. The whole machine will be tested before leaving the factory to ensure the best performance.

- Transportation and Delivery:

After your confirmation, we will arrange delivery according to the terms specified in the contract.

We will provide all the necessary shipping documents for the smooth customs clearance of your stone CNC milling machine.

We provide professional technical support and free service by phone, email, Skype, WhatsApp, online live chat and remote service. In addition, we also provide door-to-door service in some areas to ensure your satisfaction and peace of mind.

Why Choose TechPro?

At TechPro, our goal is to provide you with the best CNC solutions possible to make your woodworking projects more accurate and productive. Our state-of-the-art CNC routers are designed to meet the needs of both professionals and enthusiasts, and TechPro is the best choice for several reasons:

- Technological Innovation: For all your woodworking needs, our CNC routers, which use the latest technology, are more precise and smoother than standard wood CNC routers.

- Versatile Solutions: TechPro offers a range of models and configurations to meet your unique needs, whether you’re producing intricate designs or large-scale furniture.

- Easy-to-Use Interface: Our machine control system is simple to use, so you can focus on your creativity and craftsmanship.

- Superior Support: Whenever you need expert advice and assistance, our dedicated customer service team is at your service.

- Proven Reliability: TechPro machines are built to last and trusted by professionals in a wide range of industries.

How To Use A CNC Wood Router?

Step 1: Initial Configuration

First, make sure the computer and power supply are properly connected to the CNC wood engraver. Make sure all connections and cables are secure. Activate the CNC control software and turn on the system.

Step 2: Positioning the Machine

After the system starts, click the “Return to Home” button to restore the machine to its initial state and calibrate its coordinate system.

Step 3: Prepare Material

Use the vacuum table or fixture to fix the workpiece on the machine bed, make sure it is fixed firmly to avoid the material moving during operation and affecting the machining accuracy.

Step 4. Open the Design File

Click File -> Open on the computer in turn to import the design file to be cut into the control software.

Step 5: Selecting and Setting the Tool

Select the appropriate router bit according to the material and type of cut required for the project. The cutterhead is then securely mounted to the spindle. To prevent damage to the cutter head, make sure the router is matched to the material.

Step 6: Determine Origin

Manually move the router to the desired starting point on the material. To ensure that the machine starts cutting from the correct position, the software can be used to zero the axis at this point.

Step 7: Test Cut

Before starting a batch, determine if the machine is set up correctly by making a test cut on a piece of scrap and then observing the finished product to see if it meets the requirements.

Step 8: Getting Started

If there are no problems with the test cut, full-scale processing can begin. Keep a close eye on the machine during the first stage of processing. If there is a problem with processing, stop the machine promptly to avoid damage to the machine.

Step 9: Finish

When machining is complete, turn off the machine and carefully remove the workpiece.

Care & Maintenance

Regular maintenance of your CNC wood router ensures efficiency, extends the life of your machine, prevents unexpected breakdowns and improves safety. Our technicians have compiled the following key maintenance methods for CNC wood router machines:

- Daily Checks: Before starting the machine each day, check all cables and connections between components for looseness and make sure the voltage is stable. Before starting work, turn on the machine and do some test movements to make sure everything is in order.

- Cooling System: Keeping the cooling water clean and making sure the pump is working properly is essential for milling machines with water-cooled spindles. Avoid running the spindle without water. Regularly change the water to prevent overheating and use a large tank to enhance circulation.

- Electrical Maintenance: Regularly clean the ventilation and cooling system in the electrical cabinet. Make sure fans are working properly and use a vacuum cleaner to remove dust from the cabinet. Check that all terminal screws are tightened to ensure electrical safety.

- Rail Maintenance: To remove dust and debris, the rails should be cleaned periodically with a suitable oil. Grease should be applied after cleaning to ensure smooth operation.

- Clean Sensors: To maintain accuracy and prevent false readings, keep sensors free of dust and debris.

- Proper Shutdown: When not in use, place the head of the unit in a safe place to prevent accidental damage and always disconnect the power before unplugging any components.

- Idle Protocol: If the machine will be idle for a long period of time, it should be turned on periodically to prevent moisture buildup, especially in humid environments, which could affect the electronic components.

- Inverter Precautions: Settings have been adjusted for optimum performance, do not make unauthorized changes as this may result in damage.

- Summary of Daily Work: To extend the life of the planer, remove the cutterhead after use and leave the spindle assembly loose. Thoroughly clean the work area to prevent material buildup.

- Control Box Management: Limit access to the control box when in use to prevent debris from entering and to protect internal parts.

- Check Fasteners: To maintain structural integrity, ensure all bolts and screws are tightened regularly.

- Vacuum System: To ensure efficient operation, keep vacuum system filters clean. Run the vacuum pump occasionally to prevent rust and ensure proper operation.

- Safety Compliance: To ensure safe and effective use, always follow the machine’s operating instructions and safety precautions.

CNC Wood Router Troubleshooting

When operating a CNC Wood Router Machine, you should contact a technician when you encounter a problem to resolve the issues with the machine. Here is a troubleshooting guide for some of the most common problems:

- Abnormal Motor Noise: If the motor is making an abnormal noise, the machine may be overloaded or have an internal malfunction. It is crucial to check the motor for signs of overload or damage. If a problem is found, the motor should be repaired or replaced to prevent further damage.

- Motor running backwards: If the motor is running backwards, check the motor wiring for phase problems. Adjust the connections to the UVW terminals that connect the inverter to the spindle motor to correct the direction.

- Spindle motor overheating: Overheating of the spindle motor may signal a cooling system failure. First, make sure the pump is working properly and the circulating water is at the correct level. Inadequate cooling can result in serious motor damage.

- Motor powerless or unable to rotate: If the motor is powerless or unable to rotate, check the circuitry for any breaks or shorts. Verify that all motor wiring is in the correct phase and that cables are intact and properly connected.

- Spindle reversal: Spindle reversal during operation is usually caused by an incorrect connection between the inverter and the spindle. Replacing the connection cables will solve the problem. Please note that spindle reversal may cause the cutter to break or overheat, especially when cutting MDF. It is recommended to stop the machine immediately to prevent damage.

- Misalignment or cutting in the opposite direction: Misalignment or cutting in the opposite direction may occur due to a “phase loss” fault. If irregular movement is noticed at startup, check the circuit between the driver output terminals and the stepper motor. Identifying and repairing the open circuit will solve the problem.

- Unresponsive Machine: When the machine fails to respond to manual or automatic control, consider performing the following checks:

- Make sure the data cable connections are secure; tighten any loose connections.

- Check that the drive circuit interface is not disconnected; reconnect if necessary.

- Check that the mainframe power circuit is receiving power.

If the above problems did not solve your problem, please contact our service personnel, our after-sales personnel will contact you as soon as possible, and in the shortest possible time for you to solve all the problems of the machine!