Are you looking for an affordable laser cutting machine? Or are you looking for a high-performance, versatile laser cutting machine? If you’re confused by picking a machine, no problem, you contact us and TechPro provides you with quality options so you can purchase a quality machine at a great price without the hassle. These include fiber laser cutting machines, CO2 laser cutting machines, metal laser cutting machines, non-metal laser cutting machines, and more, and all sizes of workbenches are supported!

What is a Laser Cutting Machine?

A laser cutting machine is an automated cutting machine that integrates Computer Numerical Control (CNC) technology to cut metal, quasi-metal and non-metallic materials with the help of Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) software using a high-energy laser beam. The machines are capable of accurately cutting custom shapes, contours and holes from plates and profiles, and are widely used in the manufacture of personalized parts, logos, labels, decorative items, artwork, crafts, gifts, jewelry, lamps and puzzles for hobby and industrial-commercial use.

Laser cutting machines work by generating a laser beam through a laser transmitter, which, when focused, generates extremely high temperatures, causing the material being cut to melt or vaporize rapidly, resulting in precise cutting. A laser cutting system consists of a number of components, including the machine base and frame, CNC controller, laser generator, power supply, laser tube, laser head, lenses, mirrors, water chiller, stepper or servo motors, air cylinders, air compressor, air storage tank, air cooling filters, dust collector, dryer and control software.

The advantages of laser cutting machines are their flexibility and efficiency. It can handle a wide range of material thicknesses with virtually unlimited cut shapes compared to traditional manual and mechanical cutting tools. The laser cutting machine is considered the best solution for modular and automated production in modern manufacturing because of its high precision, good cut quality and non-deformation of parts.

Working Principle

The working principle of a laser cutting machine is based on the high energy density and high precision characteristics of a laser beam. A laser beam is a type of light produced by the jumping of atoms, molecules or ions, and its properties are different from those of ordinary light. The laser beam relies on spontaneous radiation in its initial stages, but subsequent processes are completely controlled by the excited radiation, resulting in a laser with extremely high purity, a very small divergence angle and very high coherence.

Laser cutting is a highly automated process that utilizes the high power and dense energy of a focused beam to melt or vaporize a wide variety of materials such as metals, wood, acrylics, plastics, fabrics, leathers, foams, and other materials to achieve precise cuts.

In the CNC system, the laser generator outputs a high-frequency beam to form a beam with a specific frequency and pulse width. The beam passes through the transmission and reflection of the optical path system and is focused by the focusing mirror group to form a tiny high energy density spot on the material surface, which melts or vaporizes the material at an instantaneous high temperature. Each laser pulse creates a small hole in the material. Under the control of a computer numerical control (CNC) system, the cutting head and the material are subjected to continuous relative motion and punching according to the design file, thus cutting the material into the desired shape.

The process parameters (e.g. cutting speed, laser power, auxiliary gas pressure) and movement trajectory during the cutting process are precisely controlled by the CNC system. The auxiliary gas blows away the slag at the cutting kerf at a certain pressure. The laser beam is focused into a high power density beam through the optical circuit system and irradiates the surface of the material to the melting or boiling point, while the high pressure gas coaxial with the beam blows away the molten or vaporized material. As the beam moves relative to the material, the material is eventually cut.

Different laser powers are used to cut materials of different thicknesses. Generally, thicker materials require higher laser power. Users should choose the appropriate laser power and process parameters according to the specific cutting needs to achieve the best cutting results.

Applications of Laser Cutting Machine

Laser cutting systems are used to cut and process materials in many industries. It utilizes a laser as the hardware tool to produce a concentrated beam of light to make fast, neat and precise cuts in a variety of material surfaces, allowing for complex and detailed designs to be achieved to meet a variety of industrial and commercial needs. Below is a list of the main uses of laser cutting:

- Personalization and digital printing applications: enabling on-demand design and production of products that meet individual customer requirements, such as personalized gifts, customized awards and trophies.

- Medical technology sector: Playing a role in the manufacture of fine medical devices and laboratory equipment, ensuring a high standard of accuracy and consistency in equipment components.

- Educational and architectural modeling: providing accurate model cutting services for academic programs, such as model making for architectural designs.

- Electronics industry: Highly accurate cutting and engraving in the production of electronic devices such as smartphones and laptops, as well as the manufacture of computer components and other fine electronics.

- Consumer Goods Manufacturing: Laser cutting technology is used in the manufacturing of everyday consumer goods such as toys, watches, handicrafts and other products.

- Die cutting and mold making: Creating accurate mold components for subsequent mass production processes.

- Sign and Display Production: Producing signs, labels and displays for trade shows that provide high quality visual effects.

- Electronics and automotive industry: for the production of high-precision components, such as data boards in the electronics industry and parts such as ball bearings in the automotive industry.

- Jewelry and fashion industry: Laser cutting offers unmatched precision and sophistication in the design and production of fashion jewelry and templates for clothing fabrics.

- Textile and Apparel Industry: For cutting and engraving paper card templates and fabrics in apparel manufacturing, increasing productivity and quality.

- Serial Number and Barcode Engraving: Engrave serial numbers and barcodes on products for tracking and verification.

- Machining industry and dataplate industry: Produces precise mechanical parts and dataplates that meet technical specifications.

- Packaging Design & Manufacturing: Performs fine cutting of packaging designs, including packaging for high-end consumer products.

Laser cutting systems have become an indispensable processing tool in these fields with the high precision, speed and extreme adaptability they offer, occupying a pivotal position in modern industry and manufacturing.

What Materials can Laser Machines Cut?

Laser cutting machines are capable of handling a wide range of materials, including metals, non-metals, quasi-metals, and some composites. Depending on the type and power of the laser, cutting results vary from material to material.

Metals

Fiber laser: It is suitable for cutting all kinds of metals, such as carbon steel, stainless steel, mild steel, tool steel, spring steel, galvanized steel, aluminum, copper, gold, silver, alloys, titanium, iron, brass and so on. These materials are widely used in the manufacture of sheet metal, metal tubes, 3D curved metals and irregular metals.

Non-metallic Materials

CO2 lasers: can cut most thin metallic and non-metallic materials, including wood, MDF, plywood, particle board, acrylic, plastic, PMMA, leather, fabric, cardboard, paper, rubber, foam and more.

Composite Materials

CO2 lasers: are also suitable for some composite materials such as carbon fiber, beryllium oxide, polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE/Teflon), phenolic resins or epoxy resins.

Specialty Materials

Glass and ceramics: Although laser cutting of these materials requires special adjustments and controls, high-precision laser cutters can process complex shapes.

Advantages

- High precision: Laser cutting can cut complex patterns very precisely, making it suitable for high-precision applications.

- Less scrap: High material utilization due to very fine cutting slits reduces scrap.

- Fast cutting speeds: laser cutting is often faster than traditional mechanical cutting methods, especially on thin sheet materials.

- Non-contact processing: laser cutting is non-contact processing, which does not produce direct mechanical stress on the material surface and therefore avoids deformation of the material.

In short, laser cutting machines excel in the processing of a wide range of materials, especially where high precision and complex patterns are required, making them an indispensable tool in modern manufacturing.

Laser Cutting Machine Price

The price of a laser cutting machine varies depending on a number of factors including brand, model, power and features. Under normal circumstances, laser cutting machines can range in price from a few tens of thousands of dollars to hundreds of thousands of dollars or even more.TechPro Laser Cutting Machine Prices:

- Low Power Laser Cutting Machines: these machines are usually suitable for small projects and cutting thin materials, they can be fitted with either a CO2 laser or a fiber laser as the laser source, their power is available between a few tens of watts to a few hundred watts, and their prices typically start at $3,000.

- Medium Power Laser Cutting Machines: This type of machine is suitable for cutting materials of medium thickness, and its price generally starts at $5,000 with a power range between a few hundred watts and one kilowatt.

- High Power Laser Cutting Machines: This type of machine is mainly used for industrial grade projects and they are capable of cutting thick metal materials. Their prices range from $6,500 to $16,000 and up. The power is above one kilowatt, making them suitable for mass production and heavy industrial applications.

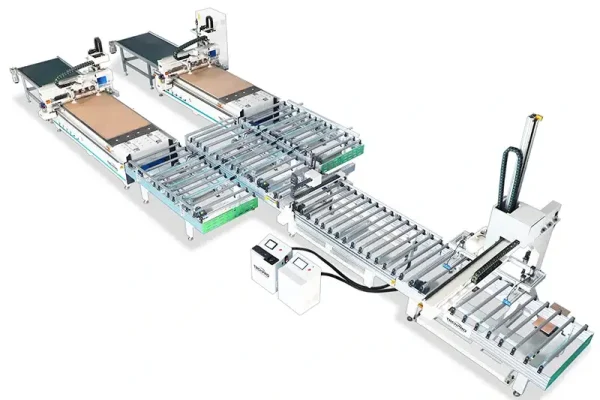

- Specialized and Customized Models: These machines may include special features and accessories such as automated feed systems, dual tables, or material-specific cutting technology. These models can cost significantly more, reaching $12,000 or more.

When purchasing a laser cutting machine, in addition to the price of the machine, there are other costs to consider, such as installation, training, maintenance, consumables, and after-sales service, which together determine the total cost of your machine purchase, as well as your buying experience. Whether you are a novice hobbyist or a professional manufacturer, contact us to get an optimal solution in the shortest possible time, allowing you to save time and money!

How to Choose an Affordable and High-Performing Laser Cutting Machine?

Before you decide to invest in a laser cutting machine, it is important to conduct thorough and in-depth planning and research. The following is a detailed buying guide to help you choose the most suitable equipment within your budget to ensure that it creates maximum value for your business in the long term.

First, clear needs, accurate planning

First, analyze your business scale and production needs in depth. Define the following key questions:

- What materials need to be cut? (Metal, non-metal or other special materials)

- What is the thickness range of the material? (Thin, Medium or Extra Thick)

- What is the daily/monthly processing volume? (Small batch customization or mass production)

- What are the requirements for cutting accuracy and speed? (High precision or high efficiency)

Determine the core parameters according to the requirements:

- Laser power: from 80 watts to 40,000 watts, the higher the power, the stronger the cutting ability, but the higher the cost.

- Table size: choose the right table according to the maximum workpiece size, customization is available in the market.

- Cutting speed and precision: according to the production demand to choose the appropriate speed and precision configuration, to avoid excessive investment.

Second, in-depth research, select quality manufacturers

After determining the needs, it is recommended to conduct in-depth research on the market, learn from the experience of peers, and understand the actual performance of different brands and models. Focus on the following aspects:

- Equipment features and performance parameters.

- Manufacturer’s technical strength and market reputation.

- Price range and cost-effective.

Select several reasonably priced manufacturers with strong technical strength for preliminary exchanges, including:

- Sampling test: provide sample materials for cutting test to verify the actual performance of the equipment.

- Field trip: visit the manufacturer’s production line, to understand the production process and quality control of the equipment.

- Detailed negotiations: in-depth communication on price, training, after-sales service.

Third, the generator and laser selection

If your main processing object is metal plate or pipe, fiber laser is the best choice. Recommended brands include:

- IPG, JPT, Raycus, MAX and other internationally recognized brands.

- These brands excel in laser power, stability and lifetime.

If you need to cut non-metallic materials (e.g. wood, acrylic, leather, fabric, etc.), CO₂ glass laser tubes are the ideal choice. Recommended brands include:

- RECI, YONGLI and other well-known brands.

- These brands have a wide range of applications in the field of non-metallic processing.

Fourth, the power supply and cutting capacity matching

Select the appropriate laser power according to the material thickness and cutting needs:

- Thin plate cutting (0.5-3mm): choose 300W-1000W equipment.

- Medium-thick plate cutting (3-10mm): choose 1000W-3000W equipment.

- Ultra-thick plate cutting (more than 10mm): choose equipment with more than 3000W.

Under the premise of meeting the cutting needs, choose the equipment with moderate power to avoid excessive investment, while reducing energy consumption and maintenance costs.

Fifth, Core components and accessories selection

In procurement, the quality of core components directly affect the performance and life of the equipment:

- Laser: choose a well-known brand to ensure stable power and long life.

- Cutting head: the choice of high-precision cutting head is critical, directly affecting the cutting quality.

- Servo motor and guide rail: to ensure the precision and stability of the movement of the equipment.

- Chiller: used to cool the laser, to ensure that the equipment for a long time stable operation.

Select high-quality accessories, such as lenses, air pumps, exhaust systems, etc., to ensure the overall performance of the equipment.

Sixth, software and control system selection

Choose Windows or macOS-based control system to ensure easy operation and friendly interface.

Powerful CAD/CAM software is a necessary tool for efficient production:

- Freeware: simple functions, suitable for small-scale production.

- Paid software: more specialized functions, suitable for large-scale production and complex processing.

Seven, quality and stability assurance

Try to choose a high market share, after-sales service system is sound brand, to ensure the quality and stability of equipment.

Do not buy low quality products without after-sales service because of low price, which will cause serious damage to the enterprise’s productivity and reputation.

Eight, after-sales service and support

Choose manufacturers who provide comprehensive after-sales service, which services include:

- Hardware and software warranty.

- Professional training system to help customers get started quickly.

- Timely fault response and solutions.

Note: In the process of use, whether the manufacturer can provide timely technical support is an important consideration in the selection of equipment.

Ninth, the procurement process

- Consultation and Quotation – Communicate with the manufacturer about the requirements and get a detailed quotation.

- Process Evaluation – Evaluate the manufacturer’s production process and quality control system.

- Place an order and production – sign a contract and arrange for production.

- Quality Control & Transportation – Ensure the equipment undergoes strict quality inspection before leaving the factory and arrange safe transportation.

- Customs Clearance & Installation & Commissioning – Complete customs clearance procedures and arrange equipment installation and commissioning.

- Support and Service – Provide follow-up technical support and training.

Conclusion

Choose an affordable and excellent performance of the laser cutting machine, not only need to deeply understand their own needs, but also need to conduct a comprehensive study of the market, choose a strong technical strength, perfect after-sales service manufacturers. Through scientific planning and rigorous implementation, you will be able to choose the most suitable equipment for the enterprise, to help the efficient development of business!