Production Line Selection Guide

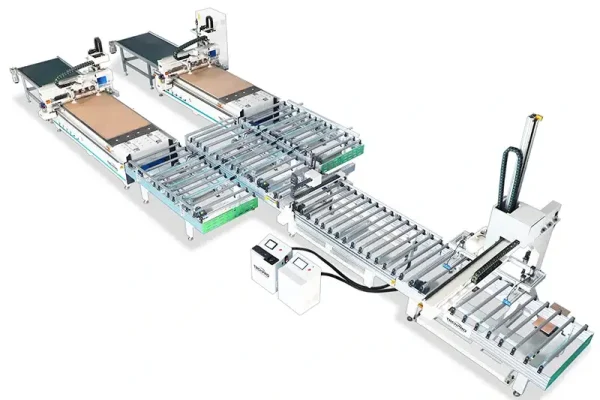

CNC Router Furniture Production Line for Sale

The CNC router furniture production line is the optimal solution for wood processing. It enables the automated production of furniture and cabinets and optimizes the furniture production process through an automated system. The line improves the efficiency, precision and scalability of furniture manufacturing by integrating computer numerical control (CNC) technology with advanced CAD/CAM software and automation systems. CNC milling machines have the advantage of reducing material waste, lowering production costs, and meeting high quality production standards for mass production or customized designs. This guide provides furniture manufacturers, woodworkers, and designers with practical insights to help you understand and utilize the latest CNC router furniture lines to stay competitive in an evolving industry.

CNC milling machines have the advantage of reducing material waste, lowering production costs, and meeting high quality production standards for mass production or customized designs. This guide provides furniture manufacturers, woodworkers, and designers with practical insights to help you understand and utilize the latest CNC router furniture lines to stay competitive in an evolving industry.

What is a CNC Router Furniture Production Line?

CNC router furniture production lines are mainly used for cutting, engraving, drilling and shaping various types of wood, such as solid wood, medium density fiberboard, plywood and composite materials, and then automatically producing furniture and cabinets. A production line integrates CAD/CAM software for design and programming, automated material handling systems, and optional upgrade components such as robotic arms and sensors. From customized designs to large-scale mass production, these systems provide consistent productivity and efficient operations.

There are several types of CNC routers used in furniture production, including 3-axis routers for standard cutting and engraving, 4-axis routers for more complex designs and mitering, and 5-axis routers for complex 3D shapes and contours. Choosing the right line for your furniture style and production requirements can increase your productivity and improve the competitiveness of your products.

A CNC furniture production line consists of several independent CNC wood machines and accessories that work together. These include multi-axis wood routers, CAD/CAM software, material handling systems (e.g. conveyor belts), and automation tools (e.g. robotic arms or sensors) used to improve accuracy and efficiency. Together, these components form a tightly integrated system capable of producing high-quality furniture with minimal human intervention.

CNC router furniture production line The advantages of automated furniture production

Automated furniture production with a CNC router furniture production line can significantly improve productivity, product quality and profitability. Here are the main advantages of CNC router furniture production lines and their impact on furniture production:

Improved Precision

Impact: CNC routers ensure that furniture components are cut, carved and shaped with high precision, achieving tolerances that are difficult to achieve manually. This results in products with perfect details and consistent quality.

Application: Suitable for complex designs, custom furniture and intricate patterns such as curved edges or carved details.

Increased Efficiency and Speed

Impact: Automation reduces manual intervention and speeds up the production process from design to final assembly. CNC routers have simultaneous multi-axis cutting capabilities, which complete tasks faster than traditional methods.

Application: Ideal for manufacturers handling large orders.

Scalability (suitable for mass or custom production)

Impact: Whether producing thousands of identical products for mass production or unique custom designs, CNC machines are flexible.

Application: Supports the business needs of both high-volume customers and niche markets.

Reduce Costs

Impact: Automated production requires fewer operators to manage the production line, thereby reducing labor costs. In addition, CNC routers optimize material usage, reduce waste, and save on raw material costs.

Application: Especially beneficial for operations that are budget-conscious and aim to maximize profits.

Reduces Material Waste

Impact: CNC routers use cutting paths designed by CAD/CAM software to ensure precision and optimal material utilization.

Application: Suitable for manufacturers who are environmentally conscious or use expensive raw materials.

Customization Capabilities

Impact: Thanks to advanced CAD/CAM integration, CNC routers enable manufacturers to efficiently produce custom designs. Custom shapes, engravings and dimensions can be easily achieved.

Application: Attracts high-end furniture brands, custom furniture manufacturers and designers looking for unique products.

Material Compatibility for Flexibility

Impact: CNC routers can process a wide range of materials, including MDF, plywood, hardwood, plastics and composites. This versatility makes it possible to produce a wide range of furniture.

Application: Useful for manufacturers exploring different furniture categories or experimenting with innovative materials.

Improved Safety

Impact: Automation minimizes the risk of work-related accidents associated with using traditional tools by reducing the need for manual handling.

Application: Helps meet industry safety standards while ensuring the health of workers.

Complex, Detailed Designs

Impact: CNC routers excel at producing intricate patterns, engravings and geometries that would be almost impossible or very time-consuming to create by hand.

Application: Essential for high-end custom furniture that requires detailed decoration.

Consistency in Production

Impact: CNC routers ensure that every product produced is exactly the same, ensuring reliable product quality in mass production.

Application: Especially important for mass production by retail chains or large furniture suppliers.

Reduced Lead Times

Impact: Automation speeds up turnaround times, enabling manufacturers to meet tight deadlines and improve delivery times.

Application: Helps companies stay competitive in a fast-paced market.

Integration with Smart Manufacturing

Impact: CNC router lines can be integrated with smart factory systems and IoT technologies to enable real-time monitoring, predictive maintenance and optimized workflows.

Application: Supports manufacturers in achieving Industry 4.0-level operations.

Environmental Sustainability

Impact: Reduced waste, energy-efficient machinery and optimized processes contribute to environmentally-friendly production.

Application: Appeals to environmentally-conscious customers and complies with green certification programs.

Reduced Maintenance Requirements

Impact: With proper care and maintenance, CNC routers are durable and reliable, reducing downtime and repair costs.

Application: Ensures continuous operation and improves ROI.

Return on Investment (ROI)

Impact: While the initial cost of implementing a CNC router line may be high, the ROI is substantial due to long-term savings in labor, material waste, and increased productivity.

Application: Attracts businesses looking for scalability and long-term growth.

Investing in a CNC furniture production line is a strategic move for manufacturers looking to improve operational precision, efficiency and scalability. By automating processes, companies can remain competitive in fast-moving markets while meeting the demand for high-quality, cost-effective and sustainable furniture production.

How Does a CNC Router Furniture Production Line Work?

CNC furniture production lines automate the furniture and cabinet manufacturing process by integrating a variety of CNC woodworking machinery. The following is a brief overview of the steps involved in the operation of this line:

- CAD Software Design: The first step is to create an accurate digital model of the structure of the furniture component to be made in CAD software.

- Programming with CAM Software: The design file is transferred to CAM software, which generates machine instructions (G-code) that control the movement of the CNC router, such as the cutting path and tool operations.

- Material Preparation: The material, such as MDF, plywood or hardwood, is prepared and fixed on the table of the CNC router, usually using a feeding system or vacuum table to ensure stability.

- CNC Machining: CNC milling machines can perform cutting, engraving or milling tasks to accurately machine raw materials into furniture components, minimizing the waste of raw materials.

- Assembly and Finishing: The machined parts will be automatically assembled into finished furniture, which will then be sanded, painted or coated by machine to improve the durability and aesthetics of the furniture.

Types of furniture produced by CNC routers

CNC router furniture production lines are versatile, and manufacturers can use them to precisely and efficiently produce various types of furniture and cabinets to meet the needs of different markets. Here are some common types of furniture that can be produced using CNC routers:

Cabinets and Drawers: CNC routers are good at cutting cabinet and drawer panels with precise dimensions, which is very suitable for making kitchens, bathrooms and storage furniture.

Tables and Chairs: From simple dining tables to complex ergonomic chairs, CNC routers can easily produce the complex parts needed for these products.

Beds and Headboards: CNC routers can carve unique patterns and engravings, making them suitable for making custom beds and decorative headboards.

Office Furniture: Efficient production of desks, shelves and workstation components, providing high-quality finishes and custom designs to meet the needs of the office space.

Custom and Specialty Furniture Applications: CNC routers enable the production of custom furniture such as decorative wall panels, modular furniture, and limited edition designs, allowing manufacturers to meet the demands of high-end or specialty markets.

By setting up a CNC router furniture production line, companies can mass produce complex furniture with exceptional quality. Whether it is mass production or custom, small batch orders, this versatile CNC router furniture production line will excel at the task.

Components of a CNC router furniture production line

A CNC router furniture production line is an integrated system designed to optimize furniture manufacturing through automation and high precision. The main components include

- CNC milling machine: the heart of the line, used to cut, carve and shape furniture parts accurately and quickly.

- CAD/CAM software: Used to design parts and generate machine instructions, ensuring accuracy and consistency.

- Dust collection systems: keep workspaces clean, minimize debris and protect equipment.

- Feeding and Conveying Systems: Automate material handling and ensure seamless movement through the production stages.

- Automation Tools: Includes robotic arms, sensors and cameras to simplify loading, unloading and quality control.

- Optional Upgrades: Choose from enhancements such as advanced nesting software, multi-spindle routers, or IoT integration to further increase processing efficiency.

These components work together to enable CNC router furniture lines to deliver high-quality output while reducing labor, material waste and production time.

Choosing the Right CNC Router for Your Furniture Production Line

Choosing the right CNC milling machine for your furniture production line can improve the efficiency of the assembly line and reduce upfront investment costs. The main considerations include:

- Machine size and cutting area: Whether you are producing cabinets or small furniture, you must choose a cutting machine with a cutting area that matches the size and type of furniture you want to produce in order to improve production efficiency.

- Spindle power and speed: A high-power spindle is suitable for processing thicker hardwoods, while much less power is required for processing lighter materials such as medium-density fiberboard. Select the appropriate spindle power according to the specific product to be processed for precise processing.

- Software compatibility: Ensure that the CNC router can be easily integrated with CAD/CAM software to simplify design and programming.

- Material compatibility: Match the router to the materials used in production, such as wood, composites or plastics.

- Budget and ROI: Assess the initial cost against the long-term benefits of reduced labor, waste and increased production speed.

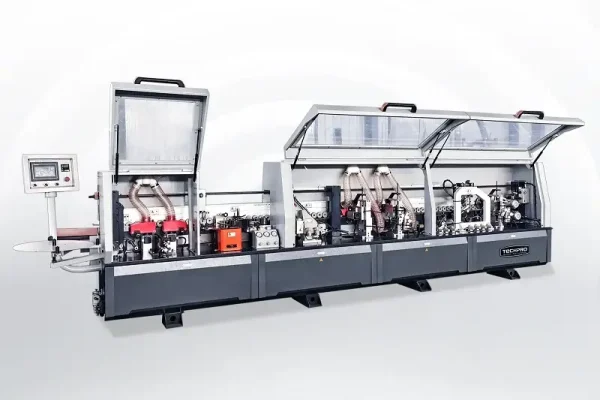

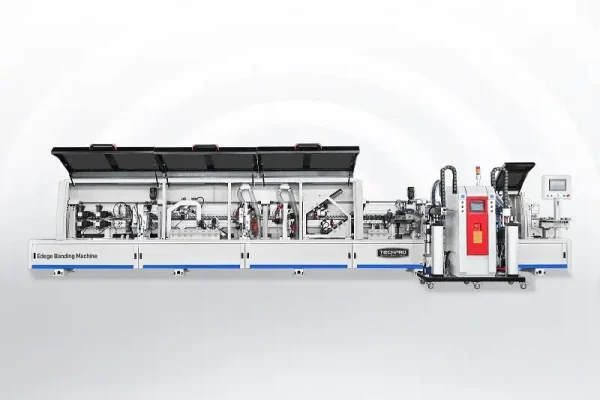

Our CNC furniture production lines

Our CNC furniture production lines are designed to meet the needs of modern furniture manufacturing, providing professional, reliable and efficient solutions for the production of panel furniture and cabinets. Designed to increase production efficiency while maintaining consistent finished product quality, our production lines combine advanced CNC technology with seamless automation to provide scalable solutions for both mass production and custom furniture projects.

Key features of our fully automated CNC furniture production lines include

- High precision and efficiency: Our production lines are equipped with the latest CNC routers, which can precisely cut and engrave a variety of materials, including solid wood, MDF, plywood, hardwood and composite panels.

- Customizable solutions: Each production line can be customized to meet specific production requirements, from small-scale customized production to mass production.

- Integrated automation: Advanced material handling systems, conveyor belt devices and optional robotic arms improve workflow efficiency. Fully automated production lines can process raw materials into finished products without human intervention.

- CAD/CAM compatibility: Seamless integration with leading design and programming software ensures a smooth process from concept to production.

- Sustainability and waste reduction: Optimized processes reduce material waste and promote cost-effective, environmentally-friendly production practices.

Whether you manufacture kitchen cabinets, office furniture or custom designs, our CNC furniture production lines deliver superior results while reducing labor, time and operating costs. By investing in fully automated solutions, furniture manufacturers can increase productivity, precision and profitability.

Why choose us?

We have been developing and manufacturing CNC machinery for many years, and our production lines are designed to be durable, easy to operate and deliver outstanding performance, based on the market’s leading furniture and cabinet products. We also provide comprehensive support, including installation, training and ongoing maintenance services, to ensure you get the most from your investment. Contact us to discover a customised solution for your business and get the best fully automated CNC furniture production line in the shortest possible time.

Cost of Implementing a CNC Router Furniture Production Line

Setting up a CNC router furniture production line requires a much larger investment than buying a CNC machine, but it can save you a lot of money in the long run. Here is a breakdown of the costs of such a production line:

Equipment Costs: The main expenses include the CNC router itself and necessary components such as CAD/CAM software, dust extraction systems, conveyor systems and robotic arms. Depending on the level of automation and the specifications of the machine, the cost of a high-end production line can range from $15,000 to over $100,000.

Installation and Training: Setting up a CNC router furniture production line requires the correct installation equipment and training for operators. These costs can vary, with most manufacturers investing between $5,000 and $20,000 in installation and training. However, TechPro offers free training for manufacturers who purchase any TechPro-manufactured CNC router production line, or our technicians can go to your factory to train your staff.

Maintenance: The maintenance costs for the machine include regular maintenance (labor costs), software application updates (completely free), and consumables such as cutting tools. Depending on the production line’s output, the annual maintenance cost is about 3-8% of the initial equipment investment.

Cost Savings: Automated furniture production using CNC processing equipment can reduce labor costs, reduce waste of resources and shorten production time, thereby bringing lasting cost savings to your business. For example, furniture suppliers can save up to 30-50% on material usage and labor costs by streamlining and automating production processes.

Return on Investment: Although the initial investment in a CNC furniture production line may seem high, the overall benefits of the line are more objective, and furniture manufacturers can expect to recoup their investment within 1-3 years, depending on your production volume and efficiency. A CNC furniture production line can also help companies expand production and take on more orders than would be possible using traditional methods, which would either take too long or be impossible.

Investing in a suitable CNC router furniture production line can help you improve productivity and product quality, but you need to carefully evaluate the costs and benefits to ensure that this is a strategic and profitable decision. If you have any questions about setting up or using the production line, please feel free to contact our team, and we will work out the best solution based on your project needs and budget.

Maintenance & Care

Correct maintenance of the various components of CNC milling machines for furniture production lines can extend the service life of the production line and ensure production efficiency. The following are the key steps to effectively maintain the production line:

Daily Cleaning: Remove dust and debris every day to prevent it from affecting the performance of the machine.

Lubrication: Regularly lubricate moving parts such as bearings and linear guides to reduce wear and ensure smooth operation of the machine.

Software Updates: Keeping CAD/CAM and CNC control software up to date will ensure optimal performance and compatibility.

Tool Maintenance: Inspect and replace worn or dull milling cutters and cutting tools to maintain machining accuracy and reduce raw material waste.

Machine Calibration: Regularly calibrate the machine to ensure cutting accuracy and finished product quality.

Preventive Maintenance: Arrange regular professional inspections to identify and resolve potential problems at an early stage.

Troubleshooting: Train staff to quickly resolve common faults.

Regular maintenance and servicing minimises machine downtime, extends the life of the production line and ensures high-quality production, thereby maximising the value of your CNC router furniture production line.

CNC Router Furniture Production Line FAQs

What is a CNC Furniture Production Line?

A CNC furniture production line is an automated system for manufacturing furniture and cabinets. It integrates CNC machine tools, CAD/CAM software and automation tools to cut, carve and drill materials such as solid wood, medium density fibreboard and plywood. It is suitable for both mass production and custom-made furniture.

What Types of Furniture can be Produced?

CNC routers can produce a wide range of furniture, including

- Cabinets and drawers for kitchens, bathrooms and storage units

- Tables, chairs and ergonomic designs

- Beds and decorative headboards

- Office furniture (tables, bookcases, workstations)

- Custom parts such as wall panels and modular designs

What are the Advantages of Using a CNC Router Production Line?

- Precision: Consistent, accurate results.

- Efficiency: Faster production and fewer errors.

- Cost savings: Reduced labour costs and less material waste.

- Flexibility: supports mass production and custom projects.

- Safety: reduces risk through automation.

- Sustainability: optimizes material use and energy efficiency.

How Does it Work?

- CAD design: creates a digital design.

- CAM programming: generates machine instructions (G-code).

- Material preparation: loads material such as MDF or hardwood.

- CNC machining: cuts, engraves and shapes.

- Assembly and finishing: assembles and finishes with sanding or painting.

What Materials can it Process?

CNC routers can process materials such as solid wood, MDF, plywood, hardwood, composites and plastics.

What are the Main Components of a Production Line?

- CNC router

- CAD/CAM software

- Dust collection system

- Material handling system (e.g. conveyor belt)

- Automated tools (robots, sensors, cameras)

How Do I Choose the Right CNC Router?

- Machine size: based on furniture dimensions.

- Spindle power: based on material thickness (higher power required for hardwood materials).

- Software compatibility: ensure CAD/CAM integration.

- Material compatibility: check if it is suitable for your materials.

- Budget: assess the cost and return on investment.

How Much Does it Cost to Implement?

- Equipment: 15,000–100,000 USD and up

- Installation and training: 5,000–20,000 USD (may be included)

- Maintenance: 3–8% of the initial investment per year

- Return on investment: usually achieved within 1–3 years

How Does it Contribute to Sustainability?

CNC routers support green credentials through precise material use, energy-efficient operation and environmentally friendly practices that reduce waste.

What are the Maintenance Processes?

- Daily cleaning to remove debris.

- Regular lubrication of moving parts.

- Software updates for CAD/CAM and CNC systems.

- Inspection and replacement of tools as needed.

- Regular professional calibration and maintenance checks.

Can it Handle Mass Production and Custom Designs?

Yes, CNC routers excel at both, and advanced software enables seamless transitions between design types.

How Long Does it Take to Implement a Production Line?

Installation and training can take anywhere from a few days to a few weeks, depending on the complexity of the system. Many manufacturers offer free training and support.

What Safety Features are Included?

Automated systems, robotic arms and dust collection minimize manual handling risks, improving safety.

What Customization Options are Available?

- Multi-axis milling machines for faster production

- Advanced nesting software for material optimisation

- IoT integration for real-time monitoring

- Robotic arms for automated material handling

Why Choose Our CNC Router Line?

- Durable and reliable machines

- Solutions tailored to your needs

- Free training, installation and support

- Energy-efficient and sustainable design

- Proven industry experience

What is the Return on Investment?

Most manufacturers achieve a return on investment within 1-3 years through labour savings, reduced waste and improved efficiency.

Can a CNC Router Produce Complex Designs?

Yes, CNC routers can produce fine engravings, 3D contours and complex patterns, making them ideal for custom and high-end furniture.

What is the Production Cycle?

CNC routers significantly reduce the production cycle compared to traditional methods, enabling orders to be completed more quickly.

Is a CNC Router Compatible with Smart Factory Systems?

Yes, CNC systems combined with smart production technologies enable real-time monitoring, predictive maintenance and workflow optimization.

How Do I Get Started?

Contact our team to discuss your requirements, budget and production goals. We will provide you with a tailored solution and guide you through implementation to maximize efficiency and profitability.