If you’re curious what the 5 axes on a CNC machine are and why they’re a game-changer in manufacturing, you’re in the right place. Understanding how these five axes move and work together unlocks the potential to create incredibly complex, precise parts in ways that traditional 3-axis machines simply can’t match. Whether you’re a seasoned engineer or just exploring CNC technology, this guide breaks down each axis, explains how 5-axis machining works, and shows why it’s transforming industries like aerospace, automotive, and medical devices. Ready to discover how five-axis CNC machines boost efficiency and precision? Let’s get started!

Understanding CNC Axes The Basics

When we talk about CNC machines, an axis refers to a direction in which the machine tool or workpiece can move or rotate. Each axis provides a specific type of movement, either linear (straight) or rotary (around a point).

Traditional CNC machines typically have three linear axes:

- X-axis: moves left to right

- Y-axis: moves forward and backward

- Z-axis: moves up and down

These three axes allow the CNC machine to perform precise cuts, drills, or engravings on flat or relatively simple 3D surfaces.

However, there are some limitations to 3-axis machining. Since the tool only moves straight along X, Y, and Z, complex shapes requiring angled cuts or multi-side machining often need multiple setups or repositioning. This can lead to longer production times, less accuracy, and limited ability to handle intricate designs. Understanding these basics shows why more advanced CNC machines, like 5-axis models, have become essential in industries demanding high precision and complex geometries.

What Are the 5 Axes on a CNC Machine

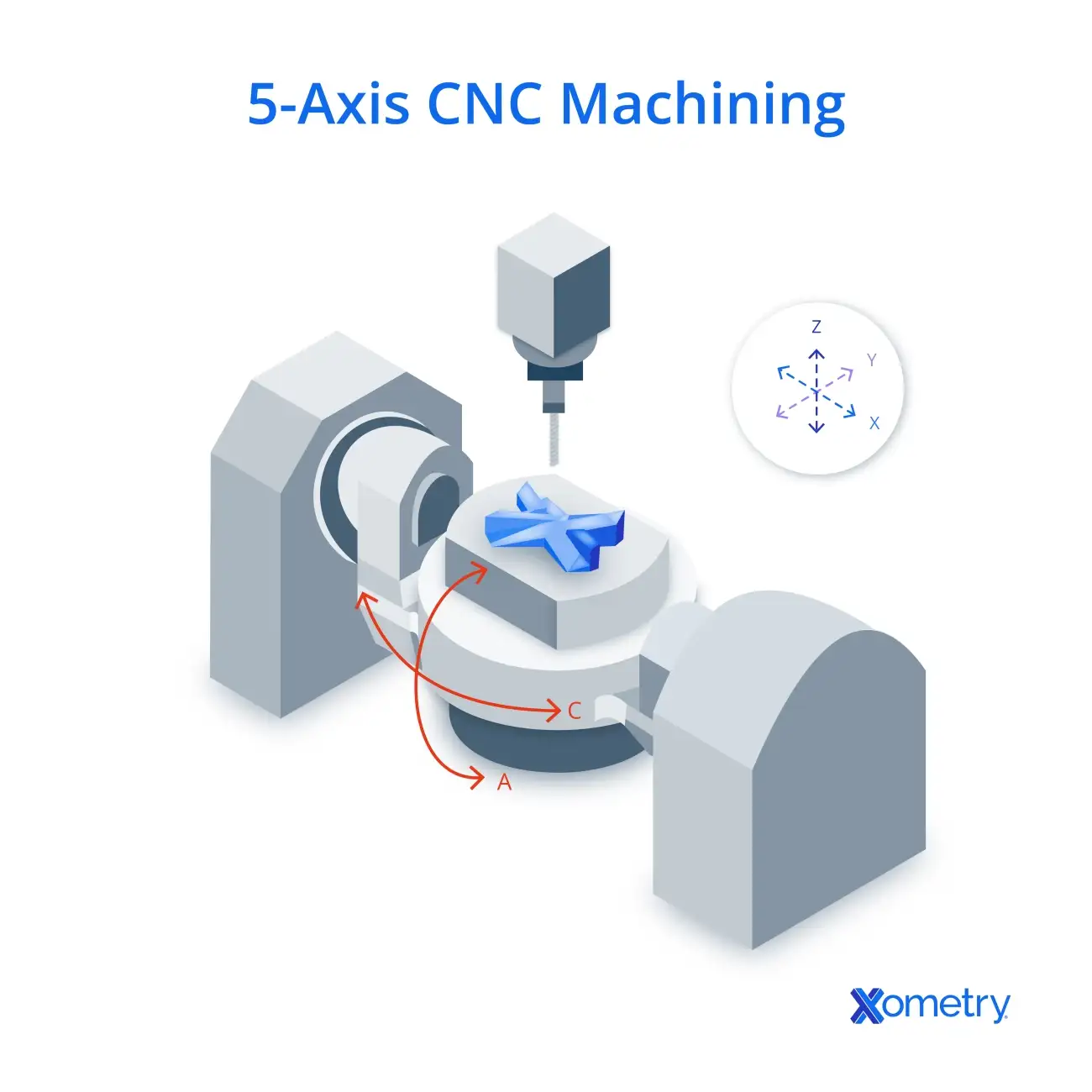

A 5-axis CNC machine adds two extra directions of movement to the traditional 3-axis setup, allowing more complex machining in one go. Here’s a quick breakdown of each axis:

| Axis | Movement Type | Description |

|---|---|---|

| X | Linear | Moves the tool left and right |

| Y | Linear | Moves the tool forward and backward |

| Z | Linear | Moves the tool up and down |

| A | Rotary (around X) | Rotates the tool or part around the X axis |

| B | Rotary (around Y) | Rotates the tool or part around the Y axis (sometimes C axis, which rotates around Z) |

The first three axes (X, Y, Z) control straight-line motions. The extra two (A and B or sometimes C) are rotary axes, meaning they rotate the tool or the part to machine tricky angles without repositioning the workpiece manually.

This mix of linear and rotary axes is what makes 5-axis CNC machining powerful and highly flexible for detailed and complex parts.

How 5-Axis CNC Machining Works The Mechanics and Control

5-axis CNC machines move the cutting tool or the workpiece along five different axes at the same time. This simultaneous movement lets the machine make complex cuts and shapes without needing to stop and reposition the part. The three linear axes—X, Y, and Z—handle left-right, forward-backward, and up-down motions. The two extra rotary axes, usually called A and B (or sometimes C), rotate the tool or table around these linear directions, allowing the machining of hard-to-reach angles.

CNC programming plays a huge role in controlling these movements. The software coordinates motions along all five axes smoothly, making precise cuts based on the design file. G-code commands tell the machine exactly how and when to move each axis to follow the part’s geometry perfectly.

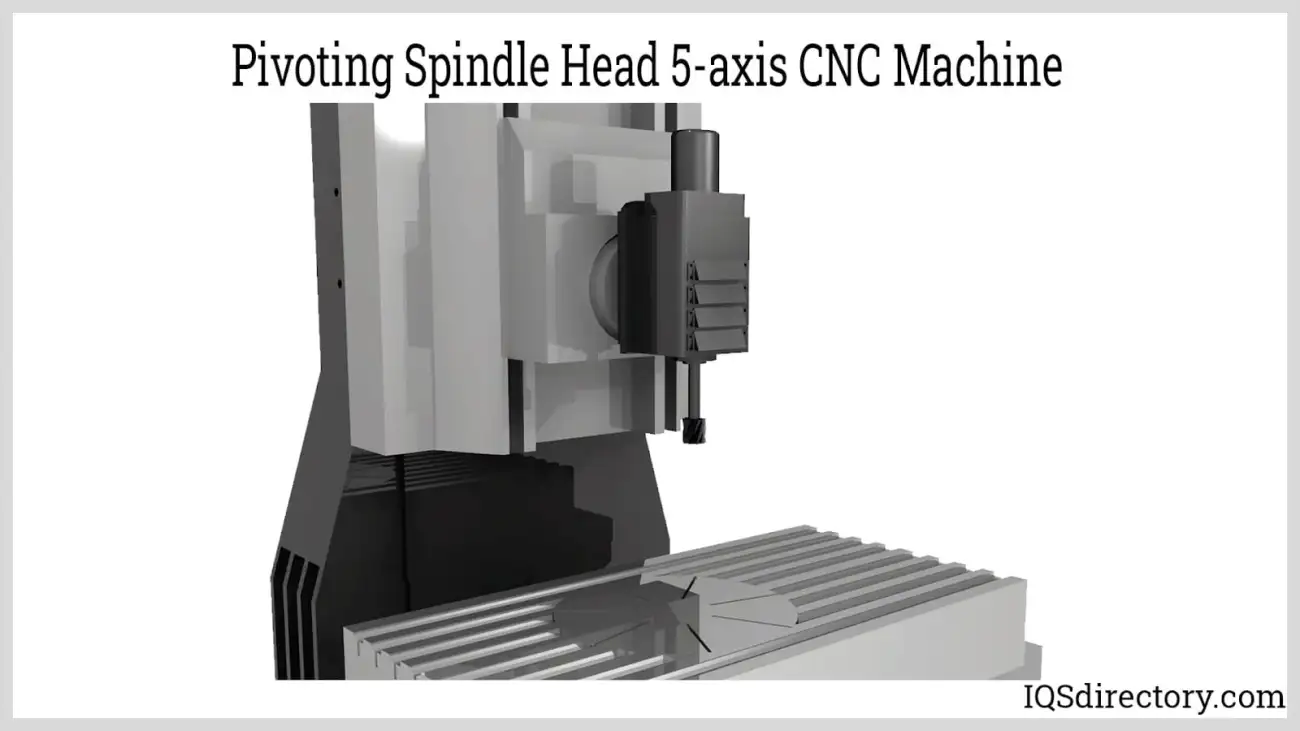

There are different types of 5-axis machines designed for various applications:

- Trunnion table machines: The workpiece tilts on a mounted table, rotating around two axes (A and B), while the tool moves linearly.

- Swivel head machines: The cutting tool itself rotates on two axes, keeping the workpiece fixed.

- Table and head rotation models: Some machines combine both table and head rotations for even greater flexibility.

This combination of linear and rotary motion gives 5-axis CNC machines the power to produce complex parts quickly and accurately, making them ideal for industries like aerospace, automotive, and medical devices.

Advantages of Using 5-Axis CNC Machines

Using a 5-axis CNC machine brings clear benefits that can boost your production and quality.

-

Increased Precision and Complexity

With 5-axis CNC machines, you can create parts with intricate details and tight tolerances that 3-axis machines can’t match. This means accurate, complex components every time.

-

Reduced Setup Time

Since 5-axis machines can approach the workpiece from multiple angles without repositioning, you spend less time setting up the job. This leads to fewer setups and faster turnaround.

-

Machine Complex Geometries in One Run

The extra two axes allow the cutting tool to reach tricky spots the traditional X, Y, and Z can’t. This lets you machine complex shapes all in one run, reducing errors and boosting efficiency.

-

Improved Surface Finish and Accuracy

The ability to tilt and rotate the tool provides better control over the cutting angle. This means smoother surfaces and better dimensional accuracy, cutting down post-processing work.

-

Industries That Benefit Most

Aerospace, automotive, and medical device manufacturing are some of the key sectors that rely heavily on 5-axis CNC machining. These industries require precise, complex parts that only 5-axis machines can consistently deliver.

For businesses in the U.S. looking to stay competitive and meet high standards, investing in a 5-axis CNC machine pays off through better parts, quicker jobs, and less hassle.

Practical Applications and Use Cases

5-axis CNC machines are ideal for jobs that require high precision and complex shapes. Here are some key areas where they shine:

- High-precision part manufacturing: When accuracy is critical, 5-axis machines deliver tight tolerances and fine details without extra setups.

- Aerospace components: Complex parts with curved surfaces and intricate features can be machined in one go, saving time and improving quality.

- Mold making and tooling: 5-axis machining handles deep cavities and sharp undercuts that 3-axis machines struggle with, making it perfect for molds and dies.

- Prototyping complex shapes: For product development, these machines quickly produce prototypes with complex geometries, speeding up the design process.

This versatility makes 5-axis CNC a solid choice for industries requiring precision and efficiency in machining complicated parts.

5-Axis CNC Machines vs 3 and 4-Axis Machines Whats the Difference

When deciding between 3, 4, or 5-axis CNC machines, it’s important to understand how their capabilities differ and when a 5-axis machine makes sense.

Comparison of Capabilities

| Feature | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

| Movement Axes | X, Y, Z (linear) | X, Y, Z + 1 rotary axis | X, Y, Z + 2 rotary axes |

| Machining Complexity | Basic shapes, flat parts | More complex curves & shapes | Very complex, multi-sided parts |

| Setup Requirements | Multiple setups often needed | Fewer setups than 3-axis | Minimal setups, 1 run does it all |

| Accuracy on Angled Surfaces | Limited | Improved with rotary axis | Excellent for angled and curved surfaces |

| Programming Complexity | Simple | Moderate | High (needs skilled programming) |

Cost-Benefit Considerations

- 3-Axis CNC machines are typically the most affordable and easiest to operate. Perfect for simple parts or high-volume runs where cost control is critical.

- 4-Axis CNC adds a rotary axis, allowing work to rotate during machining. This cuts down setups and expands complexity without a big price jump.

- 5-Axis CNC machines are more expensive upfront and require experienced operators. But they offer huge time savings by machining complex parts in one go, improving accuracy and surface finish.

When to Choose 5-Axis Over Other Configurations

- You need to machine complex geometries or multi-sided parts in a single operation.

- Your parts require machining on angled or curved surfaces that 3 or 4-axis machines struggle with.

- Reducing setup time

Selecting the Right 5-Axis CNC Machine for Your Needs

Choosing the right 5-axis CNC machine depends on a few important factors. First, think about the size of the parts you plan to make. Your machine should comfortably handle the dimensions of your workpieces without wasting space or limiting your setup.

Next, consider the programming complexity. 5-axis CNC machining requires advanced CNC programming skills and software. Make sure your team is ready or plan for training. Integration with popular CAD/CAM software is also key for smooth workflow and faster setups.

Speed and accuracy matter too. Different 5-axis machines offer varying speeds and precision levels. Choose one that matches your production pace and quality standards.

Be realistic about maintenance and training needs. More axes mean more moving parts and a steeper learning curve. Look for suppliers that offer solid support and easy access to parts or service in the U.S. market.

In , balance your requirements for size, complexity, software support, and after-sales help to pick the best 5-axis CNC machine that fits your business needs.