Applications, Projects, Plans and Ideas for 6-sided CNC Drilling Machine

What is 6-sided CNC Drilling Machine?

6-sided CNC Drilling Machine is an intelligent woodworking machine with computer numerical control (CNC) technology, which can complete the drilling, milling, slotting and special mortise and tenon structure processing of six sides of the board (such as Ramino invisible joints, hidden hinges installation, etc.) in a single clamping, without the need for manual turning operations. This equipment is mainly used in the field of customized furniture, whole cabinet and decorative engineering, which significantly improves the production efficiency and processing accuracy through fully automatic multi-face processing, and effectively reduces the labor cost and material loss at the same time.

Features & Advantages

High precision machining system

- Adopting multi-axis linkage servo drive system and intelligent positioning technology, together with the precision tool compensation function, it can realize ±0.1mm machining accuracy, and ensure that the geometric dimension and positional tolerance of the six-face holes are in line with the high-end furniture manufacturing standards.

Fully automatic machining process

- The six-face machining is completed by a single clamping, which can shorten the process time by 60-70% compared with the traditional single-face equipment, and is especially suitable for the batch production of complex shaped components. The equipment integrates an automatic tool change system (optional), which supports continuous machining of different process requirements.

Intelligent production configuration

- Material adaptability: compatible with solid wood, artificial board (density board / particle board), aluminum and wood composite panels and other mainstream materials.

- Process expandability: support three-dimensional grooves and holes, shaped contour milling, invisible connector installation and other special processes.

- Data docking: complete docking of CAD/CAM design data, realizing the seamless connection of “drawing directly to production”.

Flexible production management

- Equipped with barcode scanning system and batch management module, it can automatically identify processing parameters and flexibly switch production orders. It can not only meet the demand for single-piece customization, but also undertake large quantities of standardized production tasks.

Resource Optimization

- Integrate intelligent material optimization algorithm, improve the utilization rate of plate through automatic material discharge function, reduce rework rate with online quality inspection system, reduce the comprehensive production cost by about 35% compared with the traditional process.

Core Application Areas

Intelligent Home Manufacturing

- Whole-house customization: realize the integrated processing of invisible hinge holes (precision ±0.05mm), damping slide grooves (depth tolerance ≤0.1mm), and LED light belt hidden grooves (surface roughness Ra0.8).

- Modular furniture: support intelligent lifting system connection holes (multi-axis synchronous processing), embedded wire groove (surface adaptive processing).

- Assembled components: Completion of invisible connection holes for architectural prefabricated wall panels (deep hole machining depth of 200mm), shaped staircase positioning holes (three-dimensional spatial positioning).

Engineering Equipment Manufacturing

- Commercial facilities: display racks quick-fit interface (2D code + structural holes synchronous processing), hotel furniture anti-scratch connectors (chamfering accuracy of 0.2mm).

- Industrial support: new energy equipment structural parts (multi-material composite processing), musical instrument precision parts (micro-hole processing φ0.5-3mm).

Digital Production Services

Flexible Manufacturing Solutions

- E-commerce RTA Furniture OEM: intelligent identification system supporting daily processing of 500+ SKUs, realizing 24-hour order response.

- Industrial cloud platform: integrated CAD/CAM automatic conversion, intelligent scheduling (material utilization rate increased by 15%), quality traceability (100% inspection of key dimensions).

Creative Project Idea for 6-Sided CNC Drilling Machine

Here are all the creative project ideas for 6-Sided CNC Drilling Machine to help you get inspired in the woodworking market.

Customized Furniture Manufacturing

Panel Furniture Intelligent Manufacturing

- Modular Furniture: Developing folding/nesting furniture structure, adopting invisible pre-embedded connectors and precise positioning hole technology.

- Tool-less assembly: Apply screw-less fastening system to build high load-bearing cabinets and realize rapid disassembly and assembly.

- Shaped Processing: Create artistic furniture such as wavy laminates through 3D curved surface grooving process to ensure millimeter-level assembly precision.

- Functional integration: develop intelligent headboards with hidden wire slots and ergonomic chair structures.

Architectural Decoration Engineering Field

Decoration system integration

- Intelligent wall panels: processing three-dimensional wall decorations with interlocking structures and integrating dynamic light and shadow systems.

- Acoustic system: development of sound-absorbing wall panel system with pre-embedded fasteners for fast modular installation.

- Intelligent Windows and Doors: Manufacturing of security door systems with embedded sensors and LED light slots.

- Illuminated Stairs: Manufacture suspended treads with invisible load-bearing structure and handrails integrated with intelligent light banding system.

Kitchen and Bathroom Solutions

Intelligent kitchen and bathroom system

- IOT cabinet: integrated wireless charging module and induction lighting system.

- Functional countertops: integrated processing of drainage slots and spice compartment storage system.

- Hidden function: develop electric lifting shelves and invisible garbage disposal system.

Commercial Furniture Intelligent Manufacturing

Commercial space equipment

- Intelligent workstation: create an ergonomic workstation with cable management system.

- Variable system: produce modular hotel furniture that supports rapid reconstruction.

- Interactive display: develop intelligent display system with QR code recognition function.

Specialized Process Applications

- Musical instrument manufacturing: high-precision machining of pickup cavities and other specialized components.

- Cultural and creative products: production of CNC engraving art devices and jigsaw puzzle systems.

- Specialized equipment: research and development of laboratory corrosion-resistant furniture and customized toolboxes.

Industrial Prefabrication Field

Modular building system

- Assembled building: Produce quick-fit wall panel system with pre-buried pipes and lines.

- Emergency Furniture: Develop flat-packed, quick-assembly disaster relief furniture.

- Variable space: design folding partition and telescopic conference system.

These project solutions can give full play to the multi-dimensional processing advantages of the six-sided CNC drilling machine, promote the transformation and upgrading of the traditional manufacturing industry to intelligence and precision through process innovation, and open up high-value-added technology-based market areas.

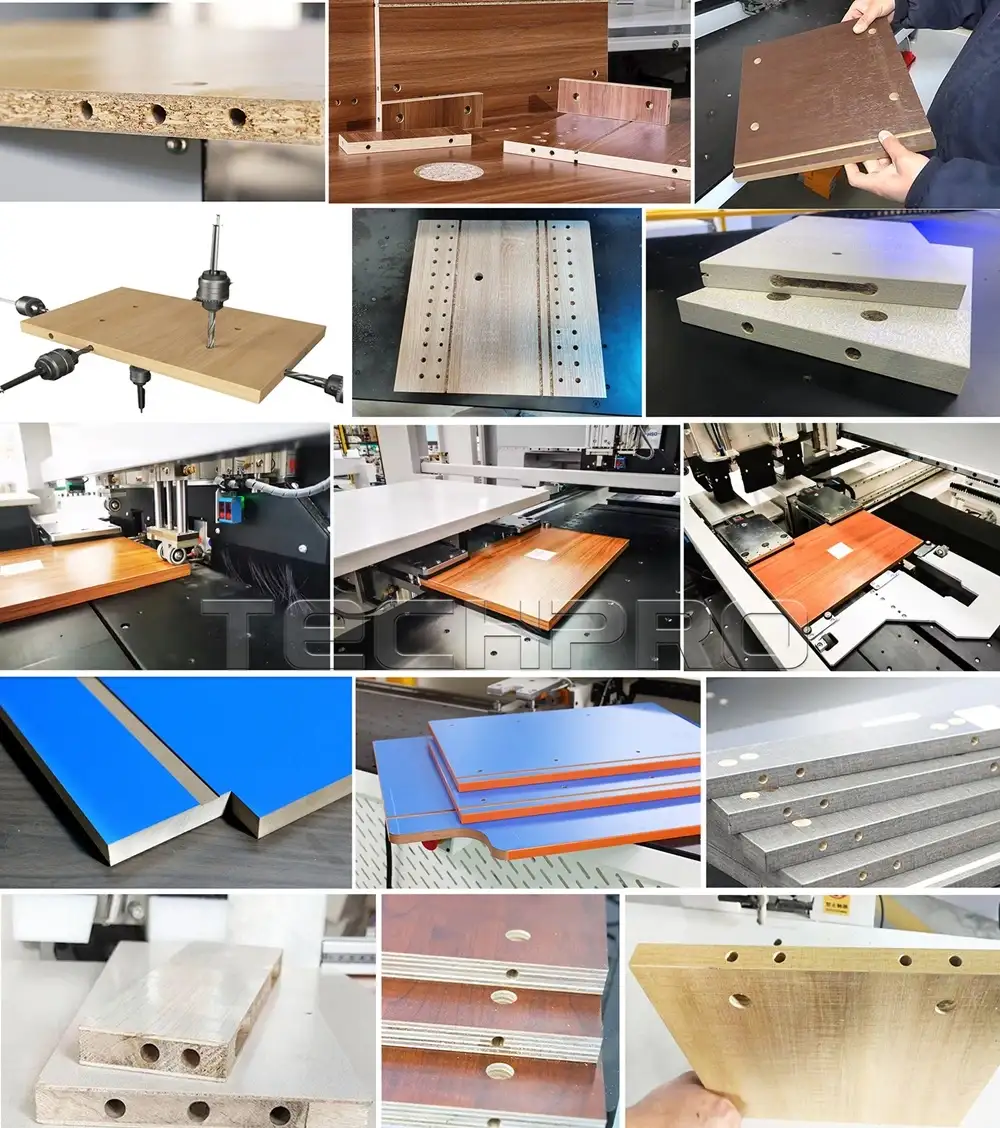

Sample of 6-sided CNC Drilling Machine

Capacity Upgrade System

Intelligent Manufacturing System Optimization

Integrated Production Line Configuration

- Six-station linkage unit: integration of automatic edge sealing (efficiency 120m/min), six-sided drilling (beat 90s/piece), surface treatment (automatic dust removal).

- Case: After upgrading the production line of a head furniture enterprise, the processing cost of a single piece decreased by 18.7%, and the yield rate increased to 99.2%.

Equipment Life Cycle Management

- Intelligent maintenance system: spindle thermal deformation compensation (accuracy maintained ± 0.03mm), tool life prediction (accuracy ≥ 95%).

- Consumables subscription service: customized drill set (matched by processing material), intelligent fixture system (supporting 200+ specifications automatic switching).

Market Expansion Strategy

New Service Models

Equipment Sharing Program

- Global market: provide equipment rental (including localized operation training) + remote technical support (5G real-time diagnosis).

- Small and medium-sized enterprises: hourly billing processing services (minimum order of 1 hour).

Green Manufacturing System

- Material Recycling Program: Artistic regeneration of trimmings (85%+ conversion rate), carbon footprint blockchain traceability (ISO14067 compliant).

Technology Evolution Planning

Intelligent Upgrade Path

Processing System Iteration

- AGV material system: realize 72-hour continuous operation (automatic tool changer magazine capacity 200+).

- Five-axis composite module: extend surface machining capability (maximum curvature R15mm).

Digital Eco-Construction

- AI process optimization engine: automatic generation of machining paths (40% efficiency improvement).

- VR training platform: 1:1 equipment simulation operation (training cycle shortened by 60%).

Industrial Collaboration Network

- Regional manufacturing centers: establish processing alliances with a 300km service radius.

- Technology licensing system: development of patented process packages (annual licensing revenue estimated at 20 million +).

Business Value System

Build Competitive Barriers Through Three Dimensions:

- Technology dimension: 8-hour quick-response delivery capability (industry average 24 hours) + composite processing accuracy ±0.1mm.

- Service dimension: provide DFM (design for manufacturability) to FATP (final assembly test) full-process program.

- Ecological dimension: Form a “equipment + consumables + services” trinity of profit models.

Implementation Suggestion:

- Key breakthrough areas: smart home (CAGR 23%) + assembly building (policy support 90%+).

- Digital infrastructure: prioritize deployment of MES cloud platform (6-month implementation cycle).

- Overseas layout: establish 3 demonstration centers along RCEP member countries (15% regional market coverage in the first year).

This program provides a sustainable development path for equipment manufacturing enterprises through a three-dimensional driving model of technology premium (gross margin 35%+), value-added services (30% increase in customer unit price), and ecological expansion (50% increase in customer stickiness).

If you are looking for high-quality 6-sided CNC Drilling Machine, please contact our sales team in time, we will give you the best solution in the shortest time.